0201, 01005 Printing and mounting Technology

date:Dec 06,2019

Return list0201, 01005 Printing and mounting Technology

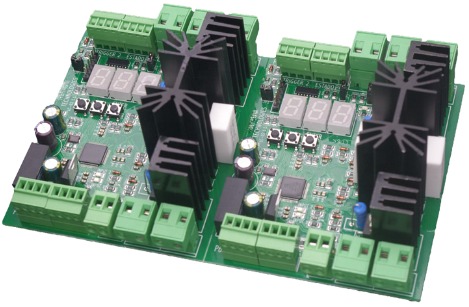

0201, 01005 solder paste printing accuracy directly affects the quality of reflow soldering. Therefore, it is necessary to correctly design PCB pads, correctly design and process stencils, equipwithhigh-precision printing machines, optimize printing process parameters, and perform 100% 3D SPI inspections.

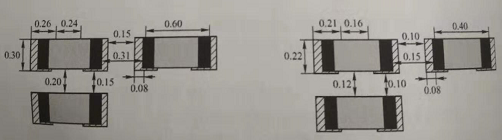

1.0201, 01005paddesign

2, Stencildesign and processing template opening shape is preferably rectangular, the inside of the opening is modified to a circular arc shape, can reduce the solder paste adhesion at the bottom of the component, the width to thickness ratio and area ratio of the opening must meet the following requirements: wide (W) thick (T) > 1.5; area ratio is greater than 0.66. The thickness of 0201 template is generally selected from 0.1 to 0.12m. The template processing method generally uses laser + electric polishing or electroforming process.

3.High-precision printing and equipped with online 3D SPI to measure the volume of solder paste.

Common defects in 0201, 01005 printing are less printing, missing printing, misalignment, continuous printing, and pollution. These printing defects can cause solder defects such as lack of tin, virtualsoldering, solder bridges, solder balls, component position shifts, and tombstones.

(3) Control of mounting height (Z axis)

When mounting on the solder paste, over-travel slip occurs, which is caused by the alloy particles of the solder paste. When the particles are larger than 20um, the component may be deflected because the particles are unevenly distributed on the pad. Any uneven surface may cause the components to deflect or move. In order to avoid component sliding, the machine must have a real-time feedback mechanism and use the side camera or laser sensor to measure the thickness of each component.

(4) Hot air leveling (HASL) board is not suitable for 0201, 01005

The surface treatment of the pads is generally electroless silver / gold (ENIG) or OSP (Organic Antioxidant Flux)

(5) Dedicated tape feeders also help to place components more accurately and faster.

(6) The application of the APC (Advanced Process Control) system significantly reduces the phenomenon of component floating and standing.