Factors affecting pcb manufacturing wave soldering quality

date:Oct 17,2019

Return listFactors affecting pcb manufacturing wave soldering quality

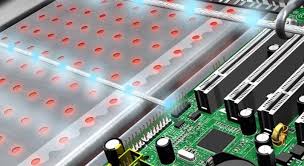

There are many factors affecting the quality of pcb manufacturing wave soldering, mainly are production materials, production equipment and production processes.

1. The impact of production materials.

The quality of solder, flux, and antioxidants, as well as proper management and usage, are important. Among them, solder and flux are the key materials to ensure the quality of PCB manufacturing electronic soldering. Solder is the material that forms the solder joint, so it directly determines the strength of the solder joint; during the soldering process, the flux can purify the soldered surface, so the activity of the flux directly affects the wettability.

2. Printedcircuitboard. Qualityof Pcb manufacturing pads, metallization and solder mask , PCB flatness, PCB pad design and layout direction (to avoid shadowing as much as possible), and the hole diameter and pad design of the insertedholes are reasonable. It is an important factor affecting the quality of welding.

3. Whether components, solder joints and pins are contaminated or oxidized, which will also affect the immersion of the material.

4.Influence of production equipment, controllability of pcb manufacturing flux spraying system, stability of preheating and welding temperature control system, stability and adjustability of peak height, smoothness of transmission system and whether or not disturbance waves are configured , hot air knife, nitrogen protection system and other functions have direct or indirect impact on welding quality

5. The impact of the production process. To find the correct settings for flux specific gravity and spray volume, preheat and soldering temperatures, belt tilt angle and transmission speed, peak height, etc., findingthe best fit between these parameters.

Previous:Prototype pcb manufacturing defect analysis and solutions

Next:How does pcb board manufacturer protect against static electricity?

Recommend

-

02Oct

Why does the PCB design generally control 50 ohm impedance?

-

17Oct

Prototype pcb manufacturing defect analysis and solutions

-

19Oct

In PCB manufacturing, wave soldering machines development direction and requirements

-

09Oct

SMD adhesive composition, storage and use process requirements