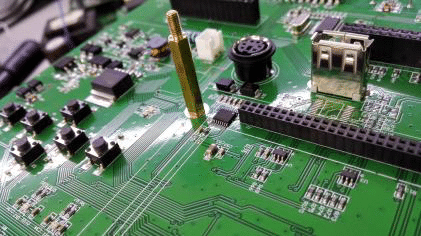

Fast PCB manufacturing reflow soldering machine

date:Oct 08,2019

Return listFast PCB manufacturing reflow soldering machine

Some projects with reflow soldering machines may achieve better standards during PCB manufacturing and solderingprocess.

Reflow soldering technology is no stranger to electronics manufacturing. The device has an internal heating circuit that heats air or nitrogen to a sufficiently high temperature.

Solder to the already attached board so that the solder on both sides of the component melts the bond plate. The advantage of this process is that it is easy to control the temperature, the PCB manufacturing soldering process can prevent oxidation, and the PCB manufacturing cost is easier to control.

FASTPCBA smtprocessing products, nitrogen and reflow soldering can bring considerable benefits to the reflow soldering machine. Nitrogen increases the wettability during use and reduces the wetting time. In this case, some mechanical operations can be eliminated. The adverse effects increase the technical content of the process and lower the temperature, thus preventing the welder from finding more scorch, but relatively easier to clean. In addition, the PCB design can also improve the utilization of the reflow soldering machine.

Previous:PCB manufacturer SMT processing online test equipment (ICT) introduction

Next:Impact of pcb factory quick turn pcb production equipment on reflow soldering quality

Recommend

-

20Oct

Why say FASTPCBA is a responsible pcb manufacturer?

-

11Oct

PCB prototype Circuit Boards Poor Plating Causes Analysis

-

21Oct

What are the characteristics of PCB assembly printed circuit boards?

-

22Oct

Good news! FASTPCBA officially entered the ranks of “national high-tech enterprises”