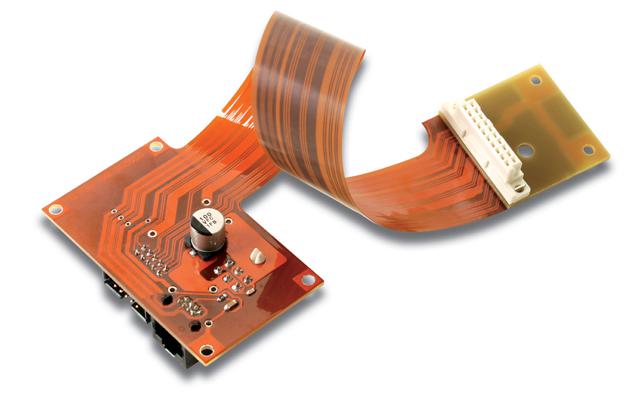

Flexible pcb manufacturing

date:Aug 16,2019

Return listFlexible pcb manufacturing

FPC is also called flexible pcb. The PCBA assembly welding process of flexible pcb is very different from the assembly of rigid circuit board. Sincethe hardness of FPC board is not enough, it is soft. If you don't use special carrier board, you can't fix and transmit. Basic SMT processes such as printing, SMT, and furnace cannot be completed.

Pretreatment of flexible pcb

The FPC board is soft, and it is generally not vacuum packed at the pcb factory. It is liableto absorb the moisture in the air during transportation and storage. It needs to be pre-baked before the SMT production process, and the water is slowly discharged. Otherwise, under the high temperature impact of reflow soldering, the moisture absorbed by the FPC rapidly vaporizes into water vapor to highlight the FPC, which is liable to cause defects such as delamination and foaming of the FPC.

1.FPC's entire manufacturing assembly process introduction

The pre-baking conditions are generally for 4-8 hours at a temperature of 80-100 ° C. In special cases, the temperature can be raised to above 125 ° C, but the baking time should be shortened accordingly. Before baking, be sure to test the sample firstlyto determine if the FPC can withstand the settingbaking temperature. Consulting appropriate baking conditionsfromthe FPC manufacturer. , the FPC stacking should not be too muchwhen baking. 10-20PNL is suitable. Some flexible pcbmanufacturers will put a piece of paper between each PNL for isolation. It is necessary to confirm whether the paper for isolation can withstand the settingbakingtemperature, if it is not necessary to remove the separator, then bake. The flexible pcb after baking should have no obvious discoloration, deformation, lifting and other defects, and it is necessary to pass the IPQC sampling test before the going on line.

2.Special carrier plate fabrication

According to the CAD file of the circuit board, read the hole positioning data of the FPC to manufacture a high-precision FPC positioning stenciland a special carrier plate, so that the diameter of the positioning pin on the positioning template and the positioning hole on the carrier plate and the aperture of the positioning hole on the FPC are match. Many FPCs are not the same thickness because they need to protect some circuitor designdue to some places are thick and some are thin, and some have strengthened metal plates. Therefore, the combination area of carrier and FPC needs to carry out machining, grinding and digging. The actual situation is processed and polished to ensure that the flexible pcb is flat during printing and placement. The material of the carrier board is required to be light and thin, high in strength, low in heat absorption, fast in heat dissipation, and small in warpage after repeated thermal shock. Commonly used carrier materials are synthetic stone, aluminum plate, silica gel plate, special high temperature resistant magnetized steel plate and so on.

Previous:FPC Board

Recommend

-

14Aug

SMA preheating concerns

-

23Aug

How to improve PCBA soldering porosity

-

21Aug

PCB circuit board copper plating process

-

04Aug

PCB copying process