For China pcb manufacturer,what effects does the white residue on the PCB have on the three anti-paint coatings?

date:Jul 03,2019

Return listFor China pcb manufacturer,what effects does the white residue on the PCB have on the three anti-paint coatings?

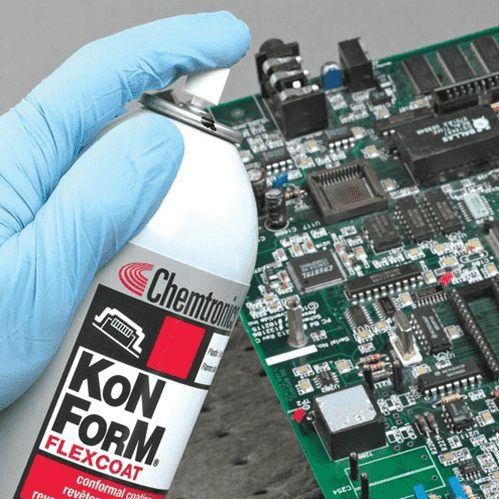

For the three anti-paint coating operation China pcb manufacturer, every time when theysee some white spot residue on the board, China pcb manufacturerwill show a very anxious expression. The three anti-paint is the last stepin all the processes, and if the frontstepis not processed well, whichwill directly affect the subsequent process, the China pcb manufacturer of the three anti-paints silently think that boardneed to be washed, why not clean it completely clean.So what effect does the white residue on the PCB have on the threeanti-paint coating?

Most of these white spots are flux residues, some crystals, dust, etc., and the flux is acidic. The residue will stay on the panel for a long time and will also reduce the protective effect of the three anti-paint.Where there is white residue, the paint film is also the easiest to fall off. First, it will affect the adhesion of the film. Over time, it will also corrode the solder joints and components of the board, affecting the reliability of the board. Even for no-clean flux, the ion residue should be controlled below 1.56ug.NaCl/m2 (J-STD-001 standard), and rosin is also required. The 123-level circuit board requires less than 200, 100, 40mg/cm2 respectively. If China pcb manufacturersay that the white liquid is from other processes, it is best to trace the root cause and ask the china pcbmanufacturer to improve the craftand eliminate the source of the pollution.

Previous:During the Pcb manufacturing process, what are the details that must be paid attention to?

Next:In China smt pcb factory, precautions for implementing lead-free soldering

Recommend

-

14Jul

Opportunities and challenges in China's PCB industry

-

14Jul

What are the reasons for the failure of solder joints in PCB assembly?

-

14Jul

What are the effects of solder balls in PCBA board guide holes?

-

20Jul

Permanent magnet rotation vibrating pelvic inflammatory disease (PID) treatment instrument smt processing