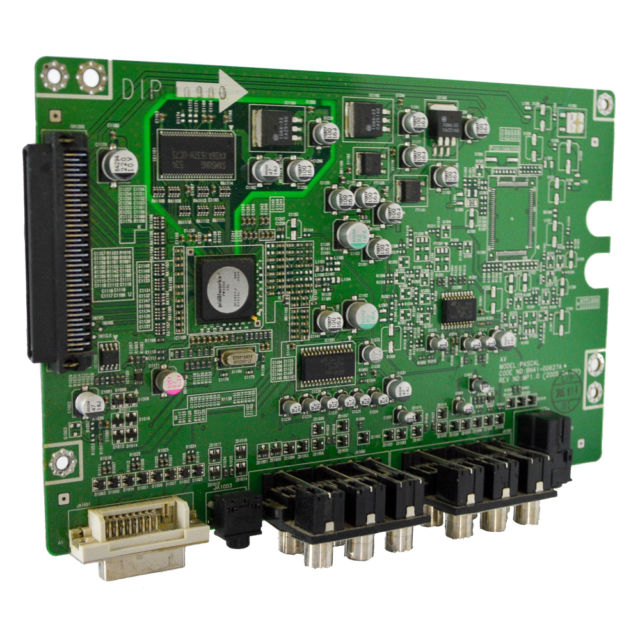

PCBA board bad phenomenon

date:May 23,2019

Return listPCBA boardbad phenomenon

1. PCBA board surface residue too much

Excessive residue on the board may be due to not preheating before welding or preheating temperature is too low, the temperature of the tin furnace is not enough; the moving speed of the board is too fast; the antioxidant is added withanti-oxidation oil; the flux is too much; The component feet and the orifice plate are not proportional (the holes are too large), so that the flux is accumulated; during the usage of the flux, the diluent is not added for a long time.

2.Corrosion, green components, blackened welding pads

Mainly due to insufficient preheating, there are many flux residues and too many harmful substances; the flux to be cleaned is used, but it is not cleaned after the welding is completed.

3.Virtual welding

Virtualwelding is a very common defect and is very harmful to the board. Mainlyrelated to the amount of flux coating is too little or uneven; some pads or welding feet are severely oxidized; pcb wiring is unreasonable; foaming tube is blocked, foaming is uneven, resulting in uneven coating of flux; operation method of hand immersion tin Improper; the chain inclination is unreasonable; the cause of peak inequality.

4. Cold welding

The surface of the solder joint is in the form of bean curd. Mainly because the temperature of the soldering iron is not enough, Or the jitter of the weldment before the solder solidifies, the poor solder joint strength is not high, the conductivity is weak, and it is easy to cause the component to open the circuit due to the external force.

5.Solder joints whitish

Rugged and dull. Generally caused by the temperature of the soldering iron is too high, or the heating time is too long. The strength of the defective solder joint is insufficient, and the failure of the componentopen circuit easily caused by the external force.