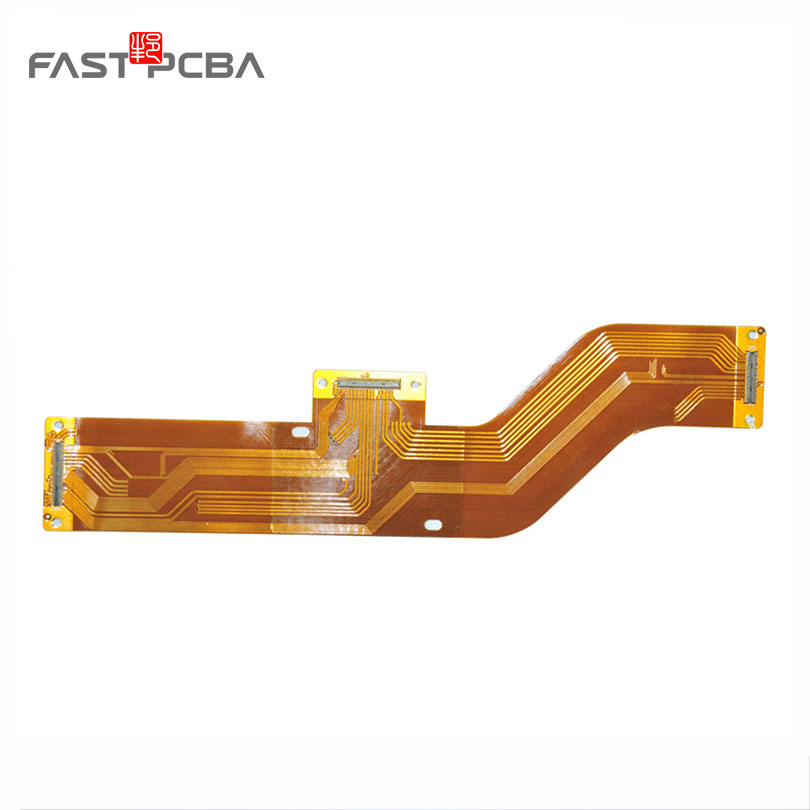

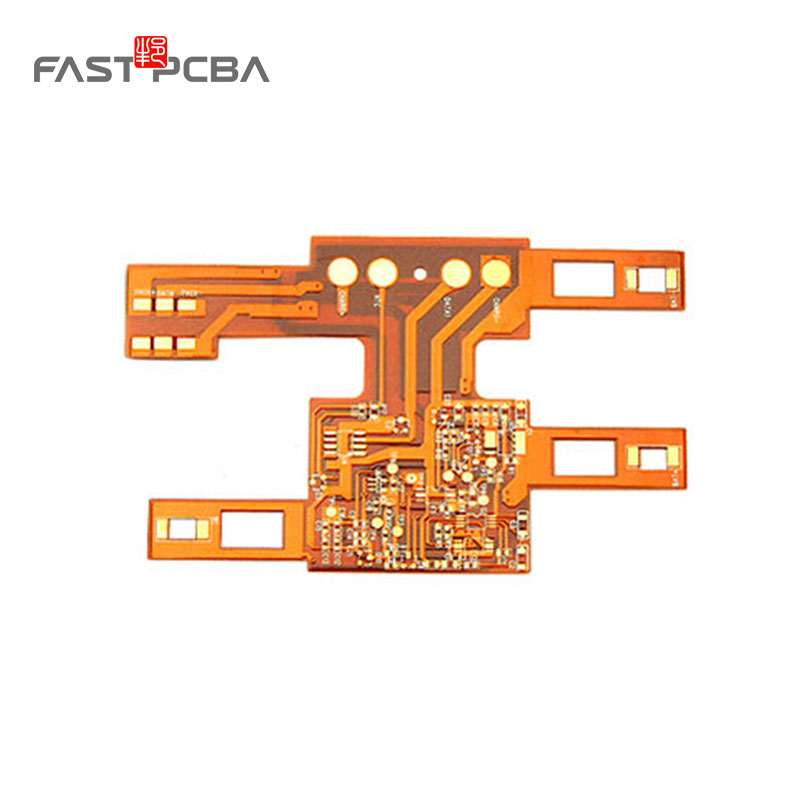

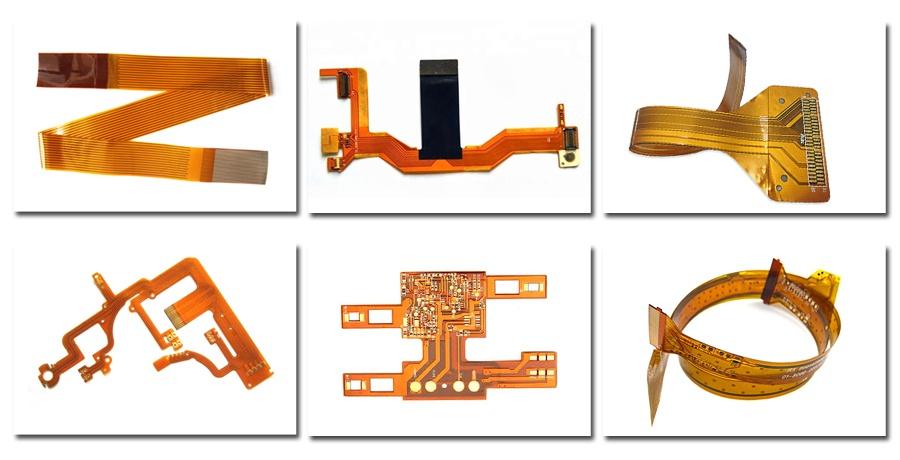

Flexible PCB Boards

Flexible pcb circuit board

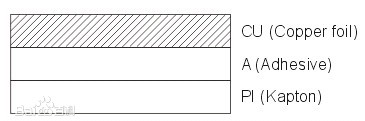

Flexible pcb circuit board is also called flexible circuit board ( FPC ) for short. It is mainly composed of CU (Copper foil) (ED or RA copper foil), A (Adhesive) (acrylic and epoxy resin thermosetting adhesive) ) And PI (Kapton, Polyimide) (polyimide film) composed of circuit boards have many advantages such as space saving, weight reduction and high flexibility. They are widely used in production and life, and the market is still expanding.

Structure of Flexible pcb circuit board

* CU (Copper foil): E.D. and R.A. copper foil

* Cu copper layer, copper skin is divided into RA, Rolled Annealed Copper and ED, Electrodeposited. The two have different characteristics due to different manufacturing principles. ED copper has low manufacturing cost but is fragile. It is used for Bend (bending) or Driver (drilling). ) When the copper surface is easy to break. RA copper has high manufacturing cost but good flexibility, so Flex PCB copper foil is mainly RA copper.

* A (Adhesive): Acrylic and epoxy resin thermosetting adhesive

* Adhesive is composed of two major systems: Acrylic and Epoxy.

* PI (Kapton): Polyimide (polyimide film)

* PI is the abbreviation of Polyimide, called Kapton in DuPont, and the unit of thickness is 1/1000 inch lmil. The characteristics are thinness, high temperature resistance, strong chemical resistance, and good electrical insulation. The current Flex PCB insulation layer has welding requirements. Kapton.

The characteristics of Flexible pcb circuit board

1. Reduce the size of the application product, save space, greatly reduce the weight, increase the function, and reduce the cost.

2. It is highly flexible and can be wired in three dimensions, and the shape can be changed according to space constraints.

3. Foldable without affecting signal transmission, anti-static interference.

4. High and low temperature resistance, flame resistance.

5. Stable chemical changes, high stability and reliability.

6. Providing more related solutions for related products can reduce assembly man-hours and errors, and increase the service life of related products.

The role of Flexible pcb circuit board

1. The function of the soft board can be divided into four types, namely lead wire, printed circuit, connector and multi-function integrated system

2. Lead wires: connections between rigid printed circuit boards, three-dimensional circuits, movable circuits, and high-density circuits.

3. Printed circuit: high-density thin three-dimensional circuit

4. Connector: low-cost connection between hard boards

5. Multi-function integration system: integration of hard board lead wires and connectors

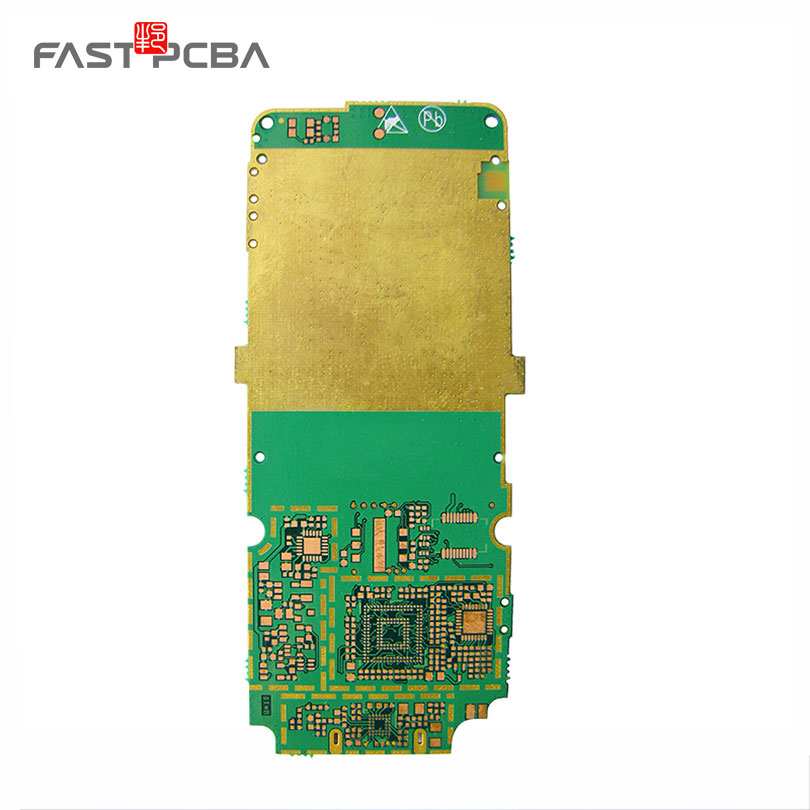

Application of Flexible pcb circuit board

Flexible pcb circuit boards are widely used in commercial electronic equipment, car dashboards, printers, hard disk drives, floppy drives, fax machines, car mobile phones, general phones, notebook computers, cameras, video cameras, CD-ROMs, Hard disks, watches, computers, cameras, medical equipment and other electronic products and equipment.

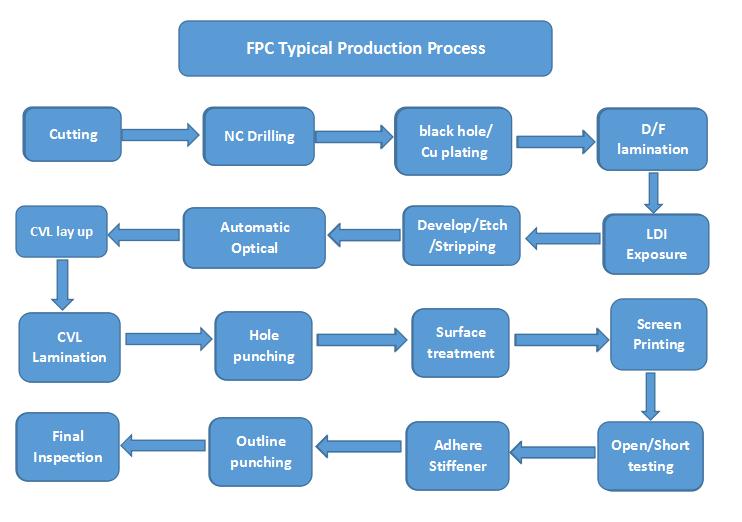

How to make flexible PCB board ?

Making Flexible PCB flow chart from multilayer flexible pcb factory, want to know more, welcoem to contact us.

FASTPCBA Service Center

FASTPCBA is Professional 20 Years PCB / PCBA Manufactuer in China, especially more than 80% circuit board are exported to oversea market. We offer 24*7 hours quotation service and engineering support. Offering: 1) PCB Assembly (including Components Sourcing & Testing) 2) Rigid PCB (1~48Layer) 3) Flexible PCB 4) Rigid-flex PCB 5) Aluminum PCB If you have any PCB projects, welcome to contact us. We sincerely hope to cooperate with you.