Prototype pcb assembly shipping packaging requirements?

date:Jul 23,2019

Return listPrototype pcb assembly shipping packaging requirements?

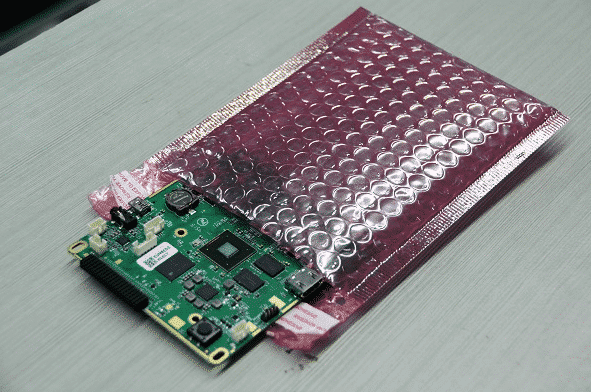

Before the prototype pcb assembly is shipped, special prototype pcb assembly packaging is required to prevent damage during transportation and to ensure that the PCBA board that is ultimately delivered to the customer is intact. Next, I will talk to you about some of the requirements for PCBA packagingbefore shipping.